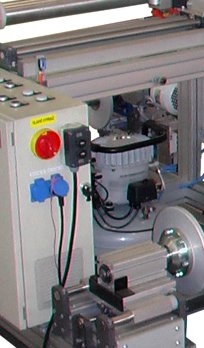

Rewinder of pipes PT 1

TECHNICAL DATA1

| Maximum diameter of the reel | 900 mm |

| Maximum width of the reel | 700 mm |

| Maximum rewinding speed | 80 m.min-1 |

| Dimensions of the machine (LxWxH) | 1300 x 1250 x 1200 mm |

| Weight of the machine | 550 kg |

| Compressed air | 0,6 MPa |

| Consumption of air max. | 4 l.hod-1 |

| Power supply | 3 x 400/230 V, 50 Hz |

| Power demand | 0,9 kVA |

USE

The equipment is used for rewinding of large laps on pipes onto a reel or into rolls with shortening to desired lengths.

FUNCTION

The rewinder consists of three basic functional parts. One part is designed for manipulation with the input reel and allows its clamping in working position and rewinding at a constant speed. It is controlled by pneumatic cylinders either by pushbuttons on the switchboard of by a switch on the operator’s post. The second part provides driving of the lining mechanism of the rewound pipe onto the output reel, including measurement of length of the rewound pipe. Drive of lining is provided by a servomotor with control on a touch display on the panel, where you can set diameter of the rewound pipe and depositing into lines is ensured automatically for all rewinding speeds. The third part allows winding onto a reel after its pneumatic clamping or into a roll on a simply attachable adapter. The used drive provides winding of material with constant tension by a change of the motor torque depending on increasing diameter of the lap. The desired tension can be preset by a potentiometer on the switchboard panel. After presetting the rewinding pipe diameter the control computer controls speed of shifting of the depositing device based on immediate peripheral speed of the reel and preset diameter of material. Any possible corrections of deposition speed can be corrected by the operator using pushbuttons for acceleration or deceleration of travel for the period when the pushbutton is pressed. This function is designed for use, above all, with insertion of a new reel.

ADVANTAGES

The rewinder ensures winding of material by a constant tension for the entire period of lapping. The rewinder ensures even winding layers in wide range of sizes of the reels and diameters of pipes. It also allows comfortable manipulation with full reels. The rewinder of pipes includes its own source of compressed air for functioning of pneumatic circuits.

1 ) Changes in technical parameters reserved.