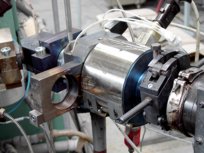

Filter of melt with a shiftable plate SP 63

TECHNICAL DATA1

| Filtration area / screen diameter | 31.7 cm² / ø 63.5 mm |

| Filter dimensions (ø max x l) | ø 150 x 320 mm |

| Filter weight | 36.50 kg |

| Max. flow (HDPE) | cca 70 kg/hod |

| Power supply | 230 V, 50 Hz |

| Heating power demand | 1.2 kVA |

USE

The equipment is used for filtration of melted polyolefins at the input to the extruding head. The filters can be used, above all, with extruding of flat and tubular foils, possibly also profiles, pipes, plates, etc.

FUNCTION

The filter consists of an input body with a sealing block inserted using a Teflon ring, shiftable plate with holes for insertion of breakers with filtration screens, output chamber and removable lever fixture for shifting of the plate. The filter is heated by two heating bodies with independent regulation of temperature. Input and output of the melt is provided with wells for measurement of pressure in the melt. Pressure difference before and after the filtration screen indicates degree of its clogging and need of its replacement. Replacement of breakers is carried out when the extruding machine is in standstill. After release of pressure in the melt the sealing block is released automatically. Then the shiftable plate with inserted breaker and clean screens can be slid into its working position using the lever.

ADVANTAGES

The filter has a relatively large sealing surface that is sufficient for one week of three-shift operation without replacement of the screen at usual level of contamination of the granulate. The replacement itself is quite fast and simple and does not need any other disassembly or additional adjustment. Input and output dimensions of the filter can be adapted to the customer’s requirements.

1 ) Changes in technical parameters reserved.

SEKON plast s.r.o., tř. T. Bati 299, 763 02 Zlín, Czech Republic, Home Page, sekon@sekon.cz